Our Services

Inspections and condition assessment

Modifications and modernization of equipment

Preparation/Supervision of tender processes for overhauls

Hazard analysis and risk assessment

Expert reports and assessments

Machine monitoring, fault diagnosis and root cause analysis

Professional seminars and training

Service:

Modifications to improve machine efficiency

Conversion of mechanically/hydraulically controlled turbine groups to state-of-the-art digital electronic control, protection, and regulation systems

Optimization of startup processes

Online machine diagnostics

Modernization of components and subsystems

Planning and Organization of Maintenance:

Planning and organization

Reengineering with modern 3D scanning

Design and calculation of turbo units, including process engineering design, rotor dynamics, and strength analysis

Construction and optimization of BOP systems (Balance of Plant) and components

Preparation of comprehensive documentation, including: P&ID schematics (Piping and instrumentation diagrams), measuring point and consumer lists, piping and valve lists, system descriptions, operating manuals and more

Expert Reports / Assessments

Preparation of Expert Reports for Energy Generation with Certified Expertise

We specialize in the preparation of expert reports in the field of energy generation, particularly for turbines and turbochargers. Our work is based on extensive expertise and internationally recognized certifications that emphasize our professional qualifications.

These certifications confirm our in-depth knowledge and expertise, enabling us to conduct well-founded evaluations and analyses in the energy generation sector. With our expertise, we ensure compliance with the highest quality and safety standards to fully meet your requirements.

Our certifications:

- Personal certification according to DIN EN ISO/IEC 17024

for gas- and steam-powered systems and equipment. - Certification according to DIN ISO 18436-2

in categories 1 and 2.

Thermography

- Inspection of IR thermography measurements on various power plant components using a microbolometer camera in the infrared range from 8 µm to 12 µm.

- Inspection of medium- and high-voltage systems, cable ducts, and switch cabinets with voltages up to 400 V.

- Inspection and monitoring of insulation on pipelines, tanks, steam generators, and steam turbines.

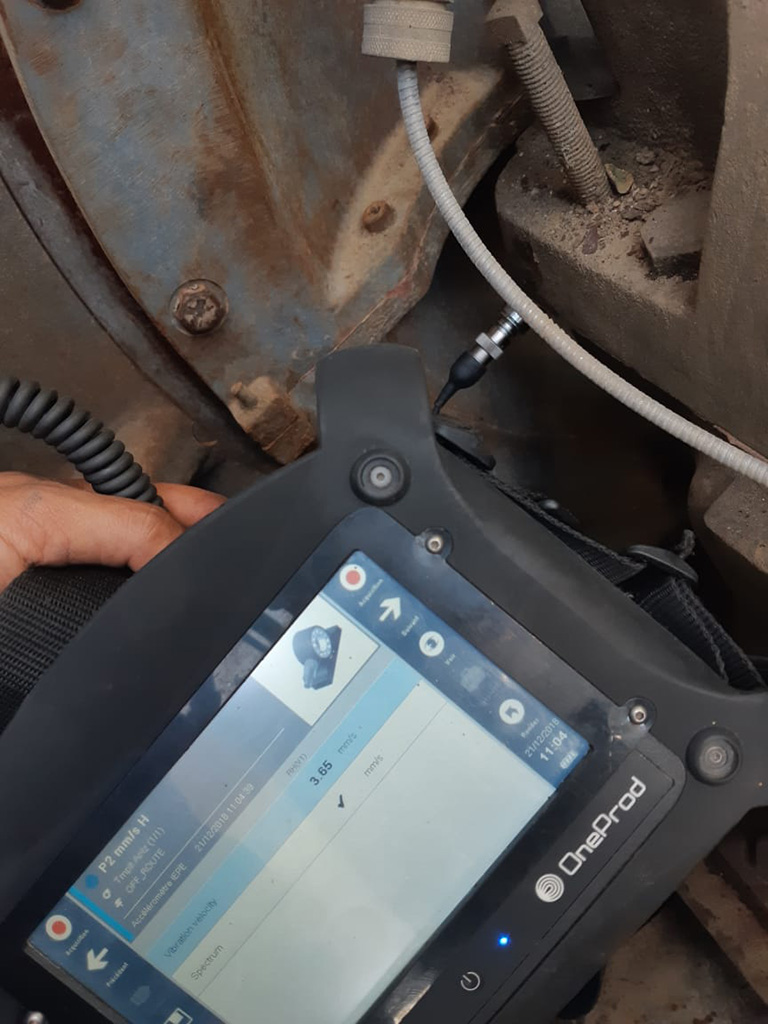

Vibration Analysis

We measure and analyze vibrations to identify the causes of unwanted oscillations. We assist you in precisely locating and replacing defective components. Additionally, we determine possible reasons for undesired vibrations, such as the incorrect alignment of moving components. One example is the precise coordination between turbine, gearbox, and generator in turbo units.

Vibrations and oscillations are inevitable during the regular operation of machinery. It is essential to distinguish between desired and undesired vibrations, as vibration levels significantly impact noise levels, service life, and the safety of machines and systems. If occurring vibrations exceed a critical threshold, immediate intervention is necessary to ensure safety and maintain the specified service life of the machine or system.

Project Management and Technical Expertise for Power Plants and Turbo Units

Our company provides comprehensive support in the field of power plants, turbo units, and associated plant components. With our many years of experience in power plant construction and turbine technology, we take over complete project management – from problem analysis to successful completion and beyond.

Our goal is to execute complex projects efficiently and reliably by utilizing our expertise in planning, manufacturing, and implementation. Trust in our know-how to ensure your projects are executed safely and successfully.

Our expertise at a glance:

- Complete project management:

We coordinate and manage your project from concept to commissioning, ensuring timely execution in compliance with the highest quality standards. - Procurement support:

We provide guidance and assistance in selecting and sourcing technical components. - Technical acceptance:

We thoroughly inspect plants and plant components for technical suitability and quality. - Commissioning:

We oversee the installation process and ensure all plant components are seamlessly put into operation.

Spare Parts in Power Plant Construction

Spare parts as a key factor for power plant operations

In today’s energy market, functioning systems and reliable spare parts are crucial for the efficiency and competitiveness of power plants. Whether pumps, bypass stations, valves, turbo units with turbines, gearboxes, or generators – the availability of precisely fitting components is essential for the stability and long-term operation of power plant systems.

We support our customers in identifying, procuring, and, if necessary, custom reengineering the right spare parts. Our focus is on minimizing downtime and ensuring the long-term operational availability of your systems.

Especially in a dynamic energy market, the rule is: Those who have the right spare parts remain operational and gain a clear competitive advantage. Trust in our expertise to secure the operational readiness of your power plant systems.

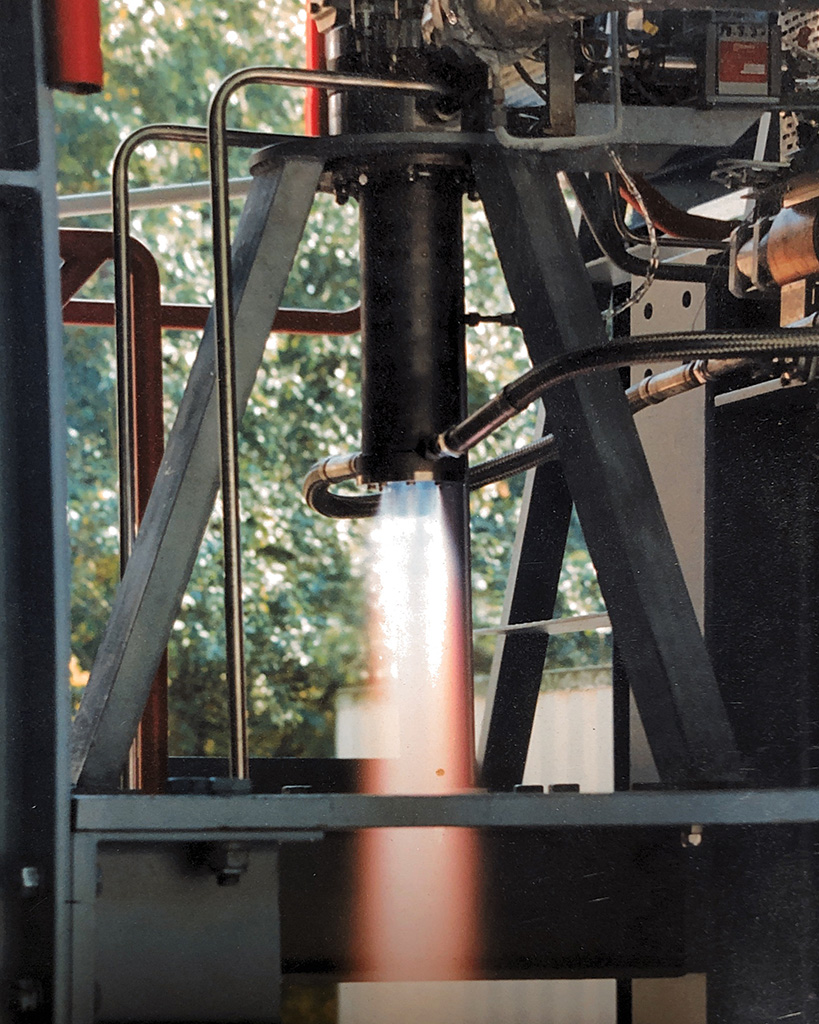

Aerospace

Expertise in test stand technology and facility construction for aerospace and rocket engineering

With my extensive professional experience in test stand technology and facility construction, we are well-equipped to provide comprehensive consulting services to companies in the aerospace and rocket industry. Our expertise particularly covers injection technologies as well as the development and construction of test stands.

With our expertise, we assist you in developing innovative solutions that meet the highest standards of precision, safety, and efficiency. Rely on our in-depth knowledge to successfully and sustainably shape your aerospace technology projects.

Damage Analysis

As an expert and assessor, I conduct on-site inspections at damage locations.

The goal is to secure evidence and determine the causes of damage. This includes comprehensive material examinations and the evaluation of relevant information. My area of expertise primarily involves inspecting turbo units, technical systems, and engineering structures.

Additionally, initial measures are derived to improve the condition of the system, and preventive strategies are developed to avoid recurring failures. The objective is to enable long-term optimizations and minimize future damages.

Key activities include:

- Conducting nationwide on-site inspections for damage analysis

- Investigating and assessing the causes of damage on-site

- Analyzing and interpreting investigation results

- Independently managing and documenting damage cases

- Direct communication with clients, usually insurance companies